-

Introduction

Built in 1985, by people who already worked in the sector for almost a decade, highly capable professionals to make a Dream become Reality, Ferdimar has today its own place in the Internal market as well as in the International Market which it conquered along these 32 years of life, in the manufacturing of Diamond Tools for Marble, Granite and Civil Constructions Industries.

Uncontested leader, with well known proof in Europe, Middle East, North Africa and South America, our Diamond Saw Blade for sawing of Marbles, of any type has raised to our main competitors great respect and admiration witch pleases us and to all we thank such distinction. Nowadays in great growth, having always as main concern the quality of its products, good service and post-sale assistance together with an enormous strength of will and honesty of the members who make part of it, our company has already an outstanding present and a certainty in the future and in the development of this area so attractive and problematic that is the manufacturing of Diamond Tools.

FERDIMAR Diamond Tools, LTD., supported by the best World Suppliers of raw materials for its industry, is in the condition of offering at the level of any other world leader company, solutions, products and improvement in the potential of the tools in the area of transformation of Marbles, Granites and Civil Construction which it proposes to manufacture, attending to the sector in which they will be applied.

-

Production

Our Production process is divided in 3 phases.

Lab

Selection of raw materials and mixes in our LAB.

Sinterization

Production of diamond segments.

Assembly

Conclusion of our tools, throw brazing of segments in several steels.

Apart from the production process we want to highlight the support given by our Technical Support department, which not only controls the functioning and performance of our products, but executes actions in our clients, in order for them to achieve the best performance of the diamond tools.

-

Laboratory

I n the laboratory we proceed to the verification of all the components that will incorporate our products. Despite being supported by the biggest and more trustful suppliers of raw material from this industry, there is always a careful analysis of our technicians at the beginning of each productive cycle.

Is in the first step that we choose the range of diamonds that will best suit the tool of our client, as well as the more adequate mixes of metal powders.

For the high performance of our products, this serious criterion of choice of the raw material to be used is indispensable. The final target is to give the client the best tool possible in accordance to the characteristics of his machine and stone that cut.

With the most advance machinery for this sector, it is the union of this with the high quality of raw materials and together with Know-how and experience acquired during the years, that we find the reason for the high quality of our products.

-

Sinterization

Sinterization is the culminating of a big and very important productive cycle. By the process of Cold compressing of the metal powders with the diamond, after submitted to the high temperatures and high pressures, we create the diamond segment, key element to our products.

After, is in this department that we control the measure and hardness of the segments, that after being approved by our quality department, will pass to the last phase of our production cycle, incorporating different products.

-

Assembly

This is the last step in the factory. We cut the steel rolls to measure, where the segments will be later brazed, obtaining after Tension treatment, the Marble Gang Saw blade for the Gang Saw Machine, the biggest product of our company, and where we are really specialists.

Besides Gnag Saw blade, our company produces High quality Discs, for several different applications.

Always supported by the most advance technology, our machinery allow us the control and tension of the blades, discs, with the maximum efficiency certifying the quality of the final product.

-

Maintenance

Our company has a team of professional that execute the assembly/disassembly of our tools in the clients, as well as inspections and repairs, satisfying any need of technical support that our client may have.

With a immediate and efficient answer, we do the maximum for the satisfaction of our clients.

-

Products

-

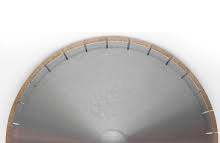

Marble Blade

Our gang saw blade has always 3 factors in consideration:

-

- The machine where it will cut (Course Length x No of Strokes);

-

- The stone the client will cut;

-

- The desire of the client of higher durability or higher speed cut.

The characteristics of the blade can change:

-

- The length of Blade (depending on the client Machine);

-

- The thickness of steel (Standard between 2.00mm and 3.5mm);

-

- The measure of segment (Different thickness, heights, models).

Following the same conditions that the Gang Saw blade, our company is able to support you, by selling only Diamond Segments of High Quality, conical and straight.

Standards measures �Full Diamond� segment:

-

- 6,5 mm Height;

-

- 7 mm Height;

-

- 7,5 mm Height;

-

- 8 mm Height.

-

-

Marble Discs

The discs are divided generally in Open (EN) or Closed (ER).

The difference between the two types its linked with the final goal of the client.

FERDIMAR advice:

-

EN Open Disc

- - Higher speed Cutting;

- - Deeper cut;

- - Higher capacity to cut harder marble.

-

ER Closed Disc

- - Higher precision;

- - Higher durability;

- - Higher capacity for Small Thickness cut.

In case of client need and desire, it is possible to supply both types in Silent Steel. The goal is to offer a disc capable of producing less noise, with the same performance.

-

-

Granite Discs

Applying the same conditions that the ones for Marble. The granite are usually divided in categories in accordance to the measure of height of its segments:

-

- Discs with 10mm height segments;

-

- Discs with 12mm Height Segments;

-

- Discs with 12,5mm Height Segments;

There is also the possibility to produce other measures used in some markets, like per example, segments with 12,5mm or 20mm height.

-

-

Diamond Wire

We produce diamond wire for quarry, mono-wire or multi-wire machine, for different applications, like marble or granite.

The size of the pearl may vary depending on the type of application and may go pearl 8.5 mm typically used for single-wire, up to 10.5mm and 11mm beads for quarry machinery.

-

Civil Construction

For the civil construction sector, our company supplies different kind of products, such as perforation Drills, Discs for the cut of Concrete, Cut of concrete with Iron, as well as segments for these applications.

-

Other Products

We produce several different kinds of finishing and polishing tools. As an example, Calibrating Rolls, Milling tools, and smaller diameter discs.

We have a wide success in special Polishing tools for polishing and finishing machines.

-

Gallery

-

Contacts

Our company is located 30 kms away from Lisbon International airport, in an important Marble area of Portugal, Pêro Pinheiro.

Thanks for your contact.

-

Edificio Ferdimar

-

Azenha Velha, Apartado 74

-

2716-901 Pêro Pinheiro - Portugal

-

Tel. +351 21 967 81 00

-

Chamada para rede fixa nacional

-

Fax. +351 21 967 81 09

-

E-mail. info@ferdimar.com

-

Ferdimar

Diamond Tools, LTD